Tower-type low-noise local ventilation fan

Still deciding? If you are interested, you need to get a sample first,Contact us!

Product Category

FBD series

Tag

Mine ventilation equipment

- Product Description

-

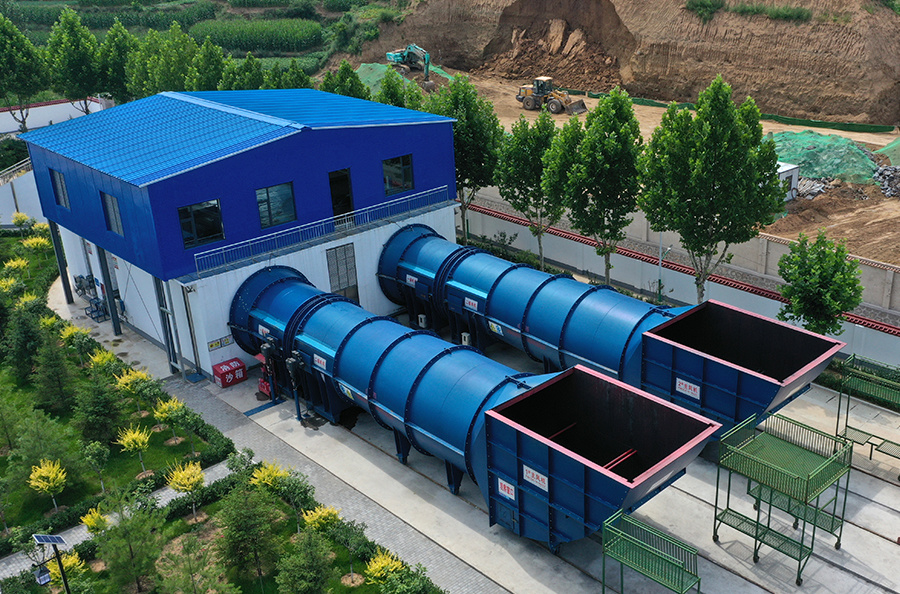

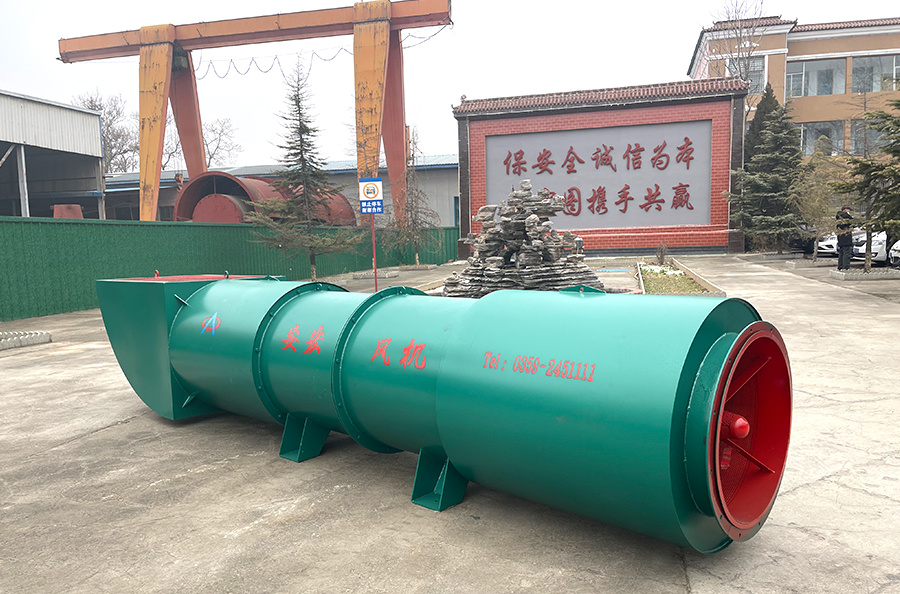

The environmentally friendly, low-noise ventilation fan is a new product improved upon the basis of double noise reduction. According to the principle of noise generation and propagation, the air intake direction is changed, and by adsorbing low and medium frequency noise and effectively isolating high frequency sound, the overall sound of the ventilation fan is attenuated. The ventilation fan consists of a tower-type silencer, inlet and outlet silencers, a primary host, a secondary host, etc. (as shown in Figure 4). According to the testing by national authoritative departments, the noise can be lower than 80 decibels.

Environmentally friendly, low-noise local ventilation fan

FBD Series Product Introduction

1. Overview

The FBD series of explosion-proof, pressure-inlet, counter-rotating axial flow local ventilation fans (hereinafter referred to as ventilation fans) comply with MT222-2007 "Technical Conditions for Counter-Rotating Local Ventilation Fans" and Q/YAF001-2011 "FBD Series Explosion-proof, Pressure-inlet, Counter-rotating Axial Flow Local Ventilation Fans" standards. They are suitable for local ventilation in underground coal mines containing methane gas or coal dust and other environments with explosive hazards, and are used with positive pressure air ducts. They can also be used as ventilation equipment for tunnel construction. Specific details are as follows:

(1) The ventilation fan uses computational fluid dynamics for multi-objective overall optimization design. The blades use aviation engine FMIA airfoil, resulting in a large area of high-efficiency operating conditions. The ventilation fan features compact structure, large air volume, high air pressure, long air delivery distance, high efficiency, energy saving, and low noise.

(2) The ventilation fan is directly driven by two YBF2 series explosion-proof motors for fan use. To extend the service life of the fan, SKF series bearings from Sweden are used for the motor bearings. (Add bearing photo)

(3) According to the different needs of users, there are 3 types of silencers to choose from;

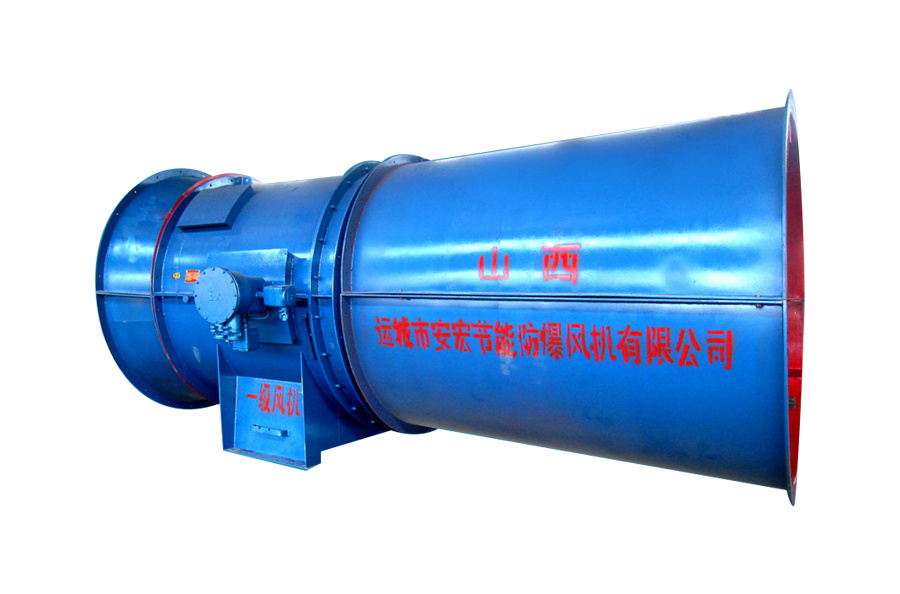

a) Ordinary outlet silencer; (Add photo)

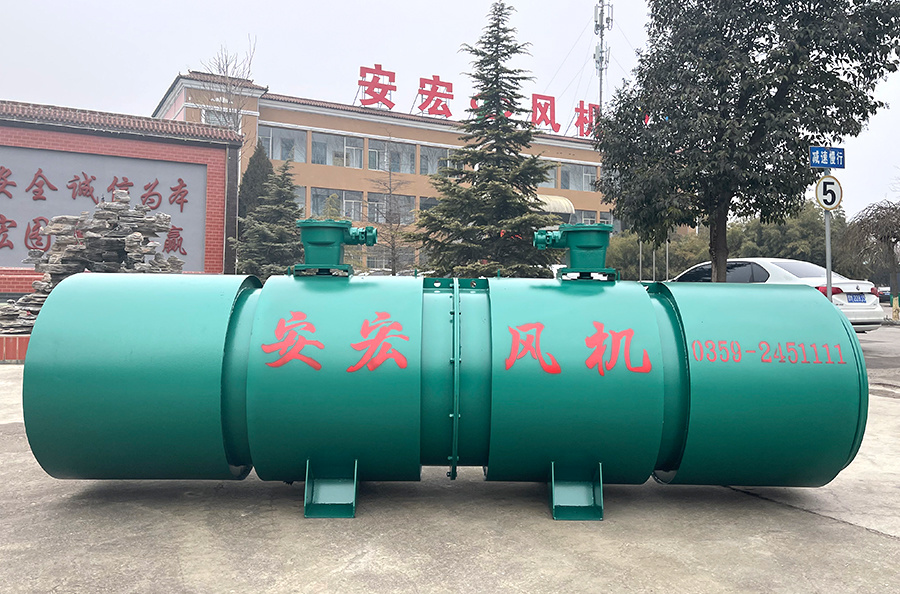

b) Inlet and outlet combined silencer; (Add photo)

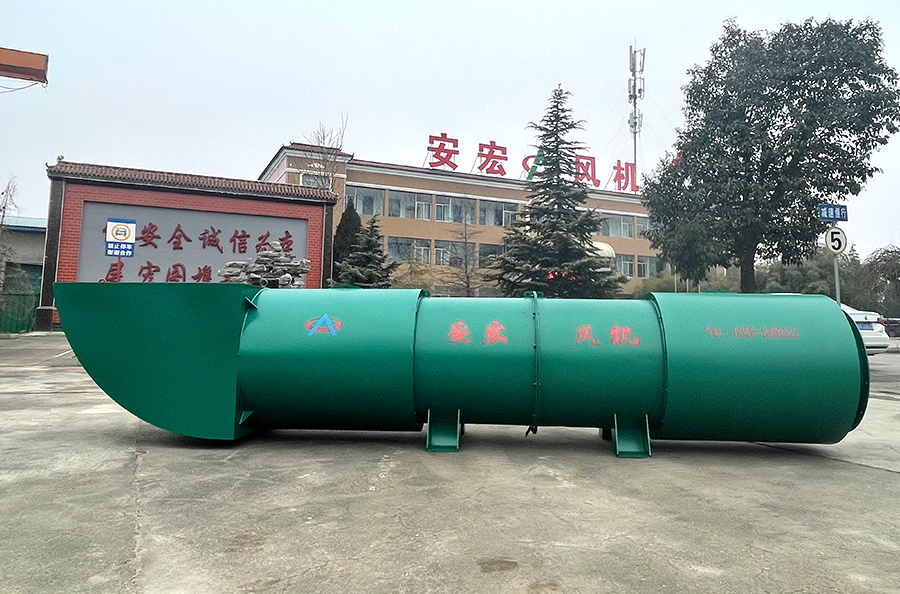

c) Side inlet, inlet and outlet combined silencer. (Add photo)

The third type (c) of combined silencer adds a side inlet component, which changes the airflow direction of the inlet without affecting the air intake, causing noise refraction. Coupled with the inlet and outlet silencers, this significantly reduces noise. Testing by the National Mine Equipment Testing Center shows that the noise level is reduced by 20-30 decibels compared to ordinary ventilation fans.

(4) The explosion-proof type of the ventilation fan and motor is: explosion-proof, and the explosion-proof mark is: ExdbI.

(5) The operating voltage is 380V/660V, 660V/1140V, and does not exceed ±5% of the rated value, and the voltage frequency is 50HZ.

For ventilation fans used underground, the roadway air supply should be greater than the maximum operating air volume of the ventilation fan.

The foundation for installing the ventilation fan should be firm and free from water splashing. The height of the edge of the ventilation fan's air inlet from the ground or top wall should be no less than 0.3m.

The air duct used should be able to withstand the highest pressure of the ventilation fan, and the diameter of the air duct should not be less than the diameter of the impeller.

(6) Service Life

The service life is no less than 5 years, and the safe operating time before the first overhaul is no less than 13000 hours.

2. Structural Features, Working Principle and Technical Parameters

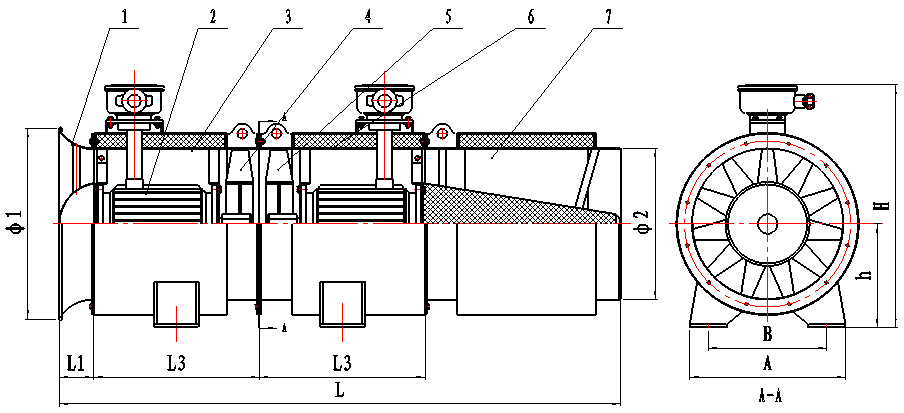

(1) The ventilation fan consists of a collector, motor, primary fan, secondary fan, motor, silencer, etc. (Figure 1 with ordinary silencer; Figure 2 with inlet and outlet silencers; Figure 3 with side inlet combined silencer). The ventilation fan shell structural components are all welded from steel plates, the inner cylinder is welded from perforated steel plates, and lined with sound-absorbing material. The motor is connected to the air duct by flange joints with bolts. The motor casing and perforated steel plate serve as the inner air duct, and the two impellers rotate counter-rotationally at the same speed.

(2) Working Principle

The ventilation fan has two impellers, the first and second stage, each driven by two explosion-proof motors of the same capacity and model. The rotation directions of the two impellers are counter-rotating. Air enters the first-stage impeller, obtains energy, and is then discharged through the second-stage impeller. The second-stage impeller also has the function of the stationary blades in an ordinary axial flow fan. While obtaining the straightened circumferential velocity component, it also adds energy to the airflow, thus achieving the high efficiency and high air pressure that ordinary axial flow fans cannot achieve.

(3) The technical parameters of the ventilation fan are shown in Figures 1-3

Figure 1 Ventilation Fan Structural Diagram (with ordinary silencer)

1. Collector, 2. Motor, 3. Primary host, 4. Primary impeller, 5. Secondary impeller, 6. Secondary host, 7. Outlet silencer

Machine Number

Motor Model

Power (kW)

Air Volume m³/min

Air Pressure (Pa)

L1

L3

L

Ф1

Ф2

A

B

h

H

Total Weight kg

4.0

YBF₂90L-2

2×2.2

200-110

300-1800

80

500

1680

490

410

400

280

310

740

280

YBF₂112M-2

2×4

220-120

350-2200

5.0

YBF₂132S-2

2×5.5

230-130

400-2750

120

580

1980

620

510

530

420

390

920

400

YBF₂132S-2

2×7.5

280-170

600-3200

6.0

YBF₂160M-2

2×11

380-220

700-3800

130

740

2340

740

610

700

580

410

1000

600

YBF₂160L-2

2×15

430-260

720-4300

6.3

YBF₂160L-2

2×18.5

500-350

750-4800

140

750

2370

780

640

720

600

435

1035

800

YBF₂180ML-2

2×22

550-360

850-5000

7.1

YBF₂200L-2

2×30

630-380

900-5900

150

840

2570

890

730

750

630

495

1145

1000

YBF₂200L-2

2×37

680-400

950-6100

8.0

YBF₂225M-2

2×45

780-440

1050-7500

160

1020

3000

950

820

800

680

530

1250

1450

YBF₂250M-2

2×55

900-540

1100-7800

YBF₂280S-2

2×75

1010-600

1600-8400

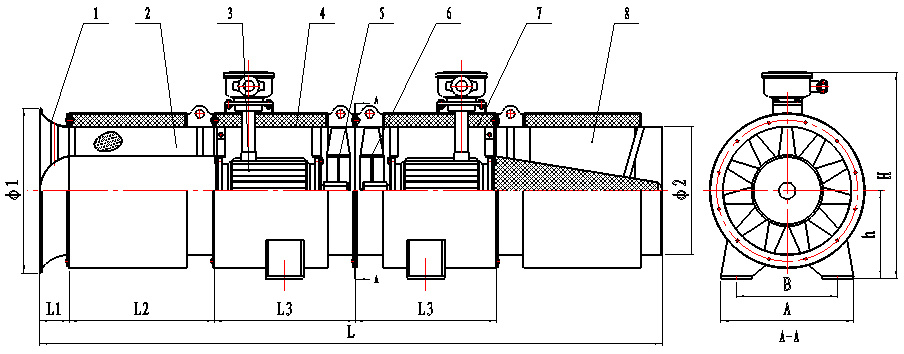

Figure 2: Ventilation system diagram (with inlet and outlet silencers)

1. Collector, 2. Inlet silencer, 3. Motor, 4. Primary unit, 5. Primary impeller, 6. Secondary impeller, 7. Secondary unit, 8. Outlet silencer

Machine Number

Motor Model

Power kW

Air Volume m³/min

Air pressure Pa

L1

L2

L3

L

Ф1

Ф2

A

B

h

H

Total Weight kg

4.0

YBF₂90L-2

2×2.2

200-110

300-1800

80

600

500

2280

490

410

400

280

310

740

350

YBF₂112M-2

2×4

220-120

350-2200

5.0

YBF₂132S-2

2×5.5

230-130

400-2750

120

700

580

2680

620

510

530

420

390

920

480

YBF₂132S-2

2×7.5

280-170

600-3200

6.0

YBF₂160M-2

2×11

380-220

700-3800

130

730

740

3070

740

610

700

580

410

1000

700

YBF₂160L-2

2×15

430-260

720-4300

6.3

YBF₂160L-2

2×18.5

500-350

750-4800

140

730

750

3100

780

640

720

600

435

1035

920

YBF₂180ML-2

2×22

550-360

850-5000

7.1

YBF₂200L-2

2×30

630-380

900-5900

150

740

840

3310

890

730

750

630

495

1145

1150

YBF₂200L-2

2×37

680-400

950-6100

8.0

YBF₂225M-2

2×45

780-440

1050-7500

160

800

1020

3800

950

820

800

680

530

1250

1600

YBF₂250M-2

2×55

900-540

1100-7800

YBF₂280S-2

2×75

1010-600

1600-8400

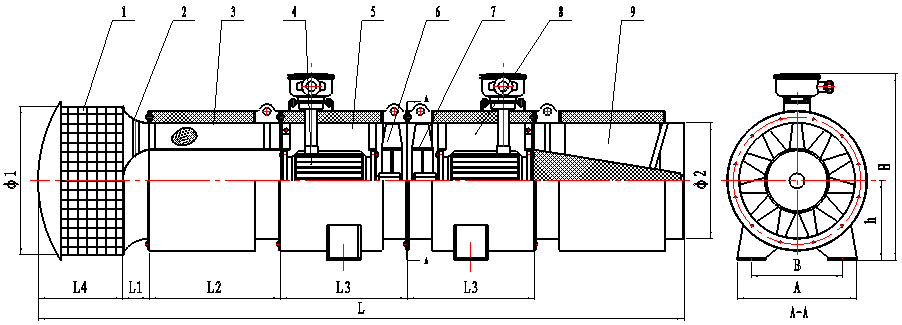

Figure 3: Ventilation system diagram (with side inlet combined silencer)

1. Side inlet device, 2. Collector, 3. Inlet silencer, 4. Motor, 5. Primary unit, 6. Primary impeller, 7. Secondary impeller, 8. Secondary unit, 9. Outlet silencer

Machine Number

Motor Model

Power kW

Air Volume m³/min

Air pressure Pa

L1

L2

L3

L

Ф1

Ф2

A

B

h

H

Total Weight kg

4.0

YBF₂90L-2

2×2.2

200-110

300-1800

80

600

500

2580

490

410

400

280

310

740

380

YBF₂112M-2

2×4

220-120

350-2200

5.0

YBF₂132S-2

2×5.5

230-130

400-2750

120

700

580

3010

620

510

530

420

390

920

520

YBF₂132S-2

2×7.5

280-170

600-3200

6.0

YBF₂160M-2

2×11

380-220

700-3800

130

730

740

3420

740

610

700

580

410

1000

750

YBF₂160L-2

2×15

430-260

720-4300

6.3

YBF₂160L-2

2×18.5

500-350

750-4800

140

730

750

3480

780

640

720

600

435

1035

970

YBF₂180ML-2

2×22

550-360

850-5000

7.1

YBF₂200L-2

2×30

630-380

900-5900

150

740

840

3710

890

730

750

630

495

1145

1200

YBF₂200L-2

2×37

680-400

950-6100

8.0

YBF₂225M-2

2×45

780-440

1050-7500

160

800

1020

4250

950

820

800

680

530

1250

1680

YBF₂250M-2

2×55

900-540

1100-7800

YBF₂280S-2

2×75

1010-600

1600-8400

3. Installation and commissioning

(1) Before assembly, the radial clearance between the top of the blade and the inner cylinder of the casing must be checked. The radial clearance should be between 1.5‰~3.5‰ of the impeller diameter, and not less than 1mm; there should be no axial clearance after assembly of each casing.

(2) The impeller rotation direction must conform to the direction indicated by the casing marking.

(3) The ventilation system must be managed and operated by a designated person.

(4) The installation and use of the ventilation system must comply with the relevant provisions of the "Coal Mine Safety Regulations", and the internal and external grounding wires must be securely connected before operation.

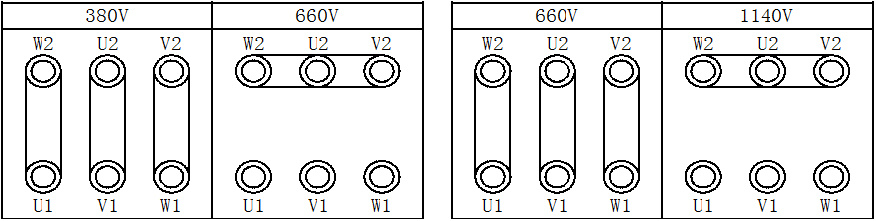

(5) The stripped connection of the motor lead-in wire should not exceed 1.5mm, and the motor should be installed according to the requirements of the motor instruction manual. Six terminals in the motor junction box can be used for two different voltages when changing the connection method (see Figure 2). The phase sequence U, V, W of the motor must correspond to the phase sequence A, B, C of the incoming external power supply. The motor rotation should be clockwise when viewed from the shaft extension end; otherwise, the motor will reverse.

Figure 2: Motor wiring diagram (Note: Motor voltage levels are 380V/660V, 660V/1140V)

4. Use and operation

(1) Preparation and inspection before use

a) The cold-state insulation resistance between the motor stator winding and the frame should be measured and must be higher than 50MΩ; if it does not meet the requirements, drying treatment should be carried out.

b) Check for safety marks and explosion-proof certification numbers.

c) All explosion-proof surface parts have no cracks or defects that affect the explosion-proof performance (new motors that have not been disassembled can be omitted).

d) The incoming cable cores must be tightly fixed with wiring plates or U-shaped washers to prevent cable movement.

e) Check whether all fasteners are complete and secure, whether the connections are reliable, whether the trial operation is flexible, whether there are any abnormal noises or sounds, impact sounds, whether the impeller rotation direction is correct, and whether the grounding wire is connected.

(2) Instructions during use

a) To ensure the long-term safe operation of the ventilation system, attention should be paid to correct use and regular maintenance.

b) When starting, turn on the first-stage ventilation system first, and after running for 5 seconds, start the second-stage ventilation system.

c) During operation, regularly check whether the sound is normal and whether there is any loosening at the connections.

d) Motor maintenance should be carried out according to the provisions in the motor instruction manual.

e) The motor bearings should be checked at least once every 6 months of operation. If the bearing grease is found to be deteriorated or leaking, it must be replaced in time. Before replacement, the bearings must be cleaned with gasoline. Use ZL-3 lithium-based grease (Sy142-75), and the amount added should be 1/2 of the net volume of the bearing chamber. (For the 180000 series sealed bearings, the grease does not need to be replaced during the service life).

f) The bearing clearance during use should be within the allowable range, the operating temperature of the bearing should not exceed the allowable value, and the sound should be normal. When the bearing is worn or damaged, it should be replaced with a new bearing.

g) If the motor is damp, it must be dried.

h) After a period of use, coal dust may block the silencer holes, so it must be flushed with high-pressure airflow; otherwise, the fan noise will increase.

i) The fan should be inspected once a month, checking all parts of the machine.

j) When the fan is not in use, it should be placed in a well-ventilated and dry place to prevent dampness, corrosion, and other damage.

5. Fault Analysis and Troubleshooting

Table 1 Main Faults and Troubleshooting Methods

Fault Characteristics

Cause of Failure

Fault Identification and Troubleshooting Methods

Metallic collision sound inside the fan

Blade rubbing against the casing

Replace the blade or casing

Foreign object entry

Remove foreign objects

Motor bearing damage

Replace the motor or bearing

Bearing has a whistling sound (accompanied by temperature increase)

Too much, too little, or unclean lubricating grease

Reduce or add lubricating grease or clean the bearing

Lubricating grease aging or incorrect type

Replace the lubricating grease

Bearing vibration and internal collision sound

Too much lubricating oil or bearing fatigue wear

Reduce lubricating grease or replace bearing

Fan and motor vibration

Impeller imbalance

Replace the impeller

Insufficient foundation hardness and damage

Check the foundation

Flange connection bolts loose

Check all connecting bolts

Insufficient pressure or air volume

Air duct leakage or insufficient motor speed

Check for leaks or check the motor

Increased vibration, intermittent noise

Fan operating under unstable conditions

Check the fan intake and exhaust conditions

One or two stages of the fan stop running

Motor damage or power failure

Replace the motor or reconnect the power

Buzzing sound when power is on but not running

Incorrect phase sequence of the motor

Swap any two power lines

Fan starts with difficulty

Low power voltage or starter malfunction

Increase power voltage or check starter

6. Matters needing attention when using the fan

When using the fan in underground coal mines, the relevant regulations in the "Coal Mine Safety Regulations" must be strictly observed:

(1) The mining face using the fan must not stop ventilation. When ventilation is stopped due to power failure for maintenance, personnel must be evacuated and the power must be cut off.

(2) Before resuming ventilation, gas must be checked. Only when the gas concentration in the airflow within 10 meters of the fan and its switch does not exceed 0.5% can the local fan be manually started.

(3) If the fan stops running due to a fault, before resuming ventilation, the gas must first be checked. Only when the highest gas concentration in the stopped ventilation area does not exceed 1.0% and the highest carbon dioxide concentration does not exceed 1.5%, and the conditions in point 2 are met, can the fan be manually started to resume normal ventilation.

(4) When using a counter-rotating axial flow fan, both sets of impellers must be started simultaneously. If one motor is damaged, the entire machine must be stopped for maintenance, and single-stage start-up is not allowed.

Tower-type low-noise local ventilation fan

Still deciding? If you are interested, you need to get a sample first,Contact us!

Product Category

Tag

Mine ventilation equipment

Get a Quote

* Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.

Related Products